Spot weld bonding repair is an eco-friendly, energy-efficient technique reducing waste, material consumption, and scrap metal generation compared to traditional welding methods. Popular in automotive dent repair, this method conserves resources, lowers environmental impact, and shortens turnaround times while maintaining structural integrity and aesthetic quality. Adopting spot weld bonding promotes sustainable manufacturing practices, facilitates recycling, and enhances companies' green credentials.

Spot weld bonding repair is revolutionizing sustainable manufacturing, offering significant environmental benefits over traditional methods. This article explores three key aspects: how spot weld techniques reduce waste and material consumption, their energy-efficient advantages in production, and the long-term sustainability it fosters in manufacturing processes. By adopting these innovative practices, industries can minimize their environmental impact while ensuring robust bonding for repairs.

- Reducing Waste and Material Consumption: How Spot Weld Bonding Minimizes Environmental Impact

- Energy Efficiency in Production: The Green Advantage of Spot Weld Bonding Techniques

- Sustainable Manufacturing Practices: Long-term Benefits of Adopting Spot Weld Bonding for Repair

Reducing Waste and Material Consumption: How Spot Weld Bonding Minimizes Environmental Impact

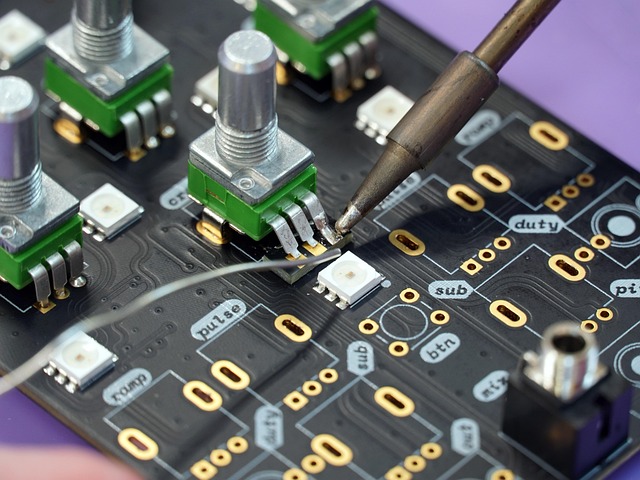

Spot weld bonding is an innovative technique that significantly reduces waste and material consumption, making it an eco-friendly alternative to traditional spot welding methods. Unlike conventional techniques that often lead to excess material removal and scrap generation, spot weld bonding repair involves precise application of adhesive to create strong bonds, minimizing the need for excessive material. This not only cuts down on the amount of scrap metal generated but also saves valuable resources used in producing new materials.

In a vehicle body shop or collision repair center, where vehicle bodywork restoration is a primary focus, spot weld bonding can play a pivotal role in sustainability. By reducing waste and material consumption, this technique lowers the overall environmental impact, contributing to a greener and more sustainable operation. Moreover, spot weld bonding repairs are known for their strength and durability, ensuring that vehicles return to their original state with minimal environmental compromise.

Energy Efficiency in Production: The Green Advantage of Spot Weld Bonding Techniques

Spot weld bonding techniques offer a significant advantage in terms of energy efficiency during production, making them an eco-friendly choice for various industries. Unlike traditional welding methods that require high heat and extensive energy consumption, spot weld bonding utilizes focused energy beams to create strong bonds between materials. This precision allows for more efficient use of resources, reducing the overall environmental impact.

In the context of vehicle dent repair or collision repair shop operations, spot weld bonding repair can play a crucial role in minimizing energy wastage. Auto body repair professionals can achieve structural integrity and aesthetic quality through this technique, while also contributing to sustainability goals. By adopting spot weld bonding, these repair shops can offer faster turnaround times and potentially reduce the carbon footprint associated with their operations.

Sustainable Manufacturing Practices: Long-term Benefits of Adopting Spot Weld Bonding for Repair

Adopting spot weld bonding techniques for repair offers a significant shift towards sustainable manufacturing practices. Unlike traditional joining methods that can lead to waste and environmental degradation, spot weld bonding is an efficient and precise process that minimizes material use and reduces overall production costs. By focusing on targeted applications, this method not only conserves resources but also lowers the carbon footprint associated with auto body restoration and car repair services.

In the long term, the benefits of spot weld bonding extend beyond economic savings. It contributes to a more circular economy by facilitating easier disassembly and recycling of components. This is particularly relevant in the auto painting sector, where efficient bonding techniques can streamline the reuse and repurposing of materials. As a result, companies offering spot weld bonding repair services not only enhance their environmental credentials but also position themselves as forward-thinking contributors to a greener manufacturing landscape.

Spot weld bonding repair offers a sustainable and environmentally conscious approach to manufacturing, with reduced waste, energy efficiency, and long-term benefits. By minimizing material consumption and optimizing production processes, this technique significantly lowers the ecological footprint of manufacturing operations. Adopting spot weld bonding as a standard practice can drive a greener future for the industry, ensuring a more sustainable and responsible manufacturing landscape.