Spot weld bonding repair is a specialized technique for collision repairs, strengthening existing welds to fix vehicle dents and auto body damage. It offers precise adhesion, efficient repair of intricate bodywork, reduced downtime, and costs. This method requires meticulous preparation, surface treatment, temperature control, and post-welding inspection for robust, long-lasting results.

Spot Weld Bonding Repair is a game-changer in collision repair, offering enhanced structural integrity and precision. This advanced technique strengthens damaged vehicle panels by reconnecting detached spot welds, effectively restoring their original strength. By understanding the basics of spot weld bonding repair, recognizing its numerous advantages, and adhering to best practices, repair professionals can deliver superior results, ensuring vehicles meet safety standards while preserving their aesthetic value.

- Understanding Spot Weld Bonding Repair Basics

- The Advantages of Using Spot Weld Bonding

- Best Practices for Effective Spot Weld Repair

Understanding Spot Weld Bonding Repair Basics

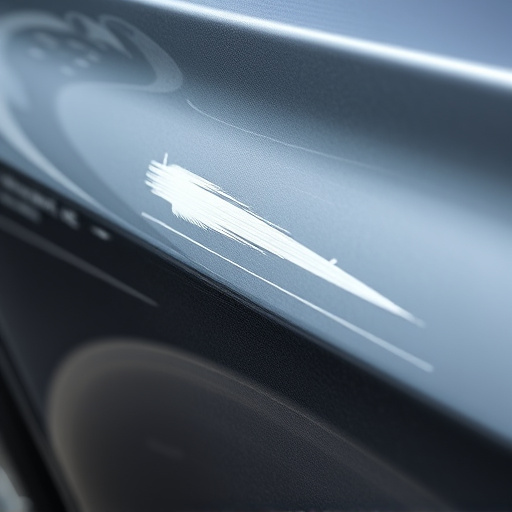

Spot Weld Bonding Repair is a specialized technique used to enhance and reinforce collision repairs, particularly for vehicle dent repair and auto body shop applications. It involves the strategic application of a strong adhesive bond directly onto existing spot welds, which are small, localized welds commonly used in vehicle manufacturing. This process strengthens the overall structure, ensuring that the repaired area can withstand significant stress without compromising integrity.

By utilizing this method, auto body shops can effectively address weak spots caused by damage, such as dents or crumples, and restore the vehicle to its original structural soundness. The spot weld bonding repair process begins with meticulous preparation, where any loose debris is removed from the weld area, and the surface is cleaned to ensure optimal adhesion. This meticulous approach guarantees a robust and long-lasting repair, making it an ideal solution for complex vehicle body repairs.

The Advantages of Using Spot Weld Bonding

Spot weld bonding repair offers several advantages over traditional methods for collision repairs, making it a game-changer in the body shop services industry. One of its key benefits is the ability to create strong, durable bonds, ensuring that vehicle dent repair and paint repair are both effective and long-lasting. This technique allows for precise and controlled adhesion, which is crucial when dealing with intricate bodywork.

Additionally, spot weld bonding provides a more efficient process, reducing the time required for repairs. By focusing on specific areas, body shops can swiftly address issues without impacting other parts of the vehicle. This not only benefits the repair process but also contributes to cost-effectiveness, making it an attractive solution for both workshops and customers seeking high-quality vehicle paint repair and dent removal services.

Best Practices for Effective Spot Weld Repair

When performing spot weld bonding repairs, adhering to best practices is essential for achieving optimal strength and durability in collision repairs. The first step involves preparing the damaged area meticulously, ensuring all contaminants are removed and the surface is clean and dry. This foundation is crucial for successful bonding. Proper surface treatment, including debonding any loose material and applying primer if necessary, enhances adhesion between the existing weld and the repair compound.

During the welding process, precise temperature control and optimal pressure application are key. Using the right equipment and following manufacturer guidelines ensures the spot weld bond reaches its maximum potential strength. Post-welding inspections should be conducted to verify the integrity of the repair, ensuring it meets industry standards and the expectations of car repair shops offering top-tier car paint services and car repair services.

Spot weld bonding repair has emerged as a game-changer in collision repairs, offering enhanced structural integrity and precision. By understanding the fundamentals and adhering to best practices, professionals can efficiently strengthen damaged vehicles, ensuring long-lasting results. The advantages of this method are clear: improved bond strength, reduced repair times, and superior overall performance. As the use of spot weld bonding continues to grow, adopting these effective strategies will be key to delivering high-quality, modern repairs.